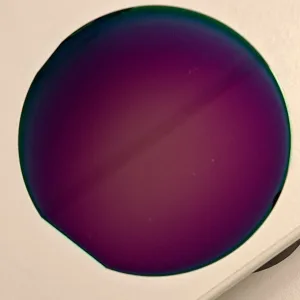

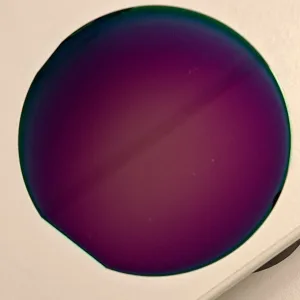

Home » Nanofabrication » Core Nanofabrication » Dielectric Deposition

Including plasma-enhanced chemical vapor deposition (PECVD) of silicon nitride (SiNx) and silicon oxide (SiOx), thermal atomic layer deposition (ALD) and e-beam evaporation of AlOx.

Including plasma-enhanced chemical vapor deposition (PECVD) of silicon nitride (SiNx) and silicon oxide (SiOx), thermal atomic layer deposition (ALD) and e-beam evaporation of AlOx.

Item | Compatibility |

|---|---|

Thermal ALD | Sample size: chips up to 4" wafers |

Materials | oxides of Al2O3; HfO2;Ta2O5 |

Typical deposition temperature | 150-200C |

PECVD | Sample size: chips up to 6" wafers |

Materials deposited | SiNx; SiOxNy; SiO2 |

Deposition temperature | 300-400C |

Whether you are new to the National Facility or have visited us before, our Getting Access page contains more information about booking our services.

Turnaround time is generally from one week, although this could be faster or slower depending on the work package; please contact us for more details.

For pricing details and more information about the services we can provide please contact us.

We’re happy to help; please contact us using the form above. Or try our searchable equipment directory for an overview of everything CORDE has to offer.